Reduce harmful emissions

Burning cleaner fuel enables diesel engines to emit lower levels of carbon dioxide.

Reduce Component Replacements

Burning cleaner fuel increases the life expectancy of fuel injectors, fuel pumps and fuel filters when working in tough mining conditions.

End Fuel-related Breakdowns

Burning cleaner fuel preserves the engine’s fuel-injectors and prolongs the life expectancy of the diesel engines of your mining machinery. Vital when operating large distances away from technical engineers.

Reduce Maintenance

Burning cleaner fuel avoids blocked fuel filters and damaged fuel pumps, which keeps costs down and your mining machinery running.

Reduce Fuel Consumption

Burning cleaner fuel improves fuel efficiency, which means you get more and better performance from every gallon. Integral for keeping ongoing operational costs down.

Reduce Cost of Ownership

Burning cleaner fuel reduces the cost of diesel engine maintenance while ending on-site fuel-related breakdowns and improving the overall performance of your mining equipment.

Product Features

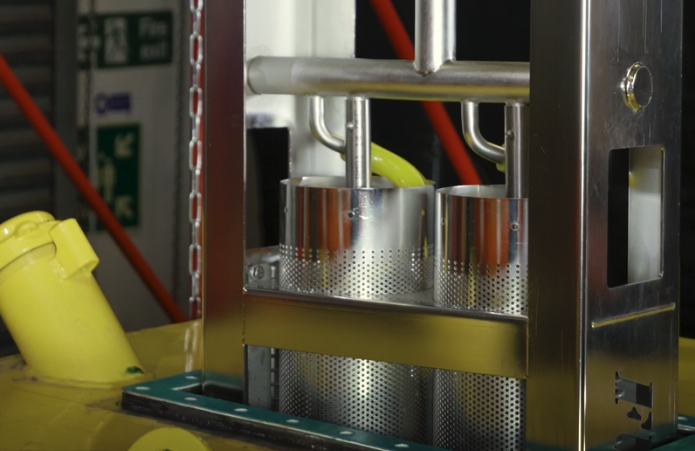

Easy to fit

Easy to fit

Installation is relatively non-intrusive and can normally take place while the tank remains on the machine. All that is required is a simple replacement of the current fuel pick-up pipe. Fitting can be completed within 60 minutes in most instances.

You can view the installation on a CAT 785 tank here

Robust

Robust

FuelActive® is proven to work from Himalayas, Andes to sub Saharan Africa in extreme temperatures and regions and in all mining applications.

FuelActive® units can deliver over 4000 litres of diesel per hour and also operate efficiently within the highly agitated fuel of a mining bed.

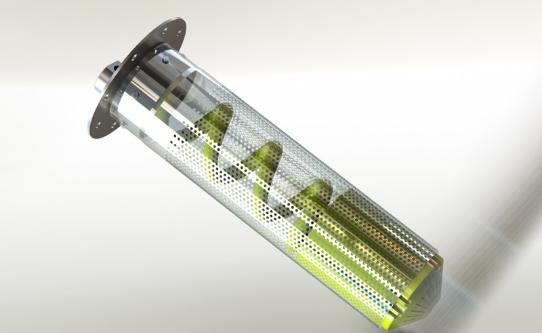

Manufacturing excellence

Manufacturing excellence

FuelActive® is ISO 9001 accredited. Units are made up of steel and plastic components which are resistant to Hydrocarbon Fuels (Diesel, Gasoline, Kerosene etc).

The product has been thoroughly tested in the field and independently tested by a TS16949 registered filter company.

Versatile

Versatile

Not confined to diesel. The physics that underpins FuelActive® functions remains true for other fuels such as petrol, kerosene, adBlue etc.

FuelActive units are often made bespoke. Bottom feed units, units capable of delivering >4,000 litres of fuel per hour and units that are fitted to unconventionally-shaped fuel tanks make up a versatile range of products.

Proven in Industry

Proven in Industry

FuelActive is proven in the mining industry with customers and OEM’s, such as Komatsu and Cummins, from around the globe.

You can find out how we’re reducing machine downtime whilst lowering fuel costs and emissions for our customers on our Customer Stories page.

Counting the cost of fuel contamination?

Read our insight on this costly issue.

Our Customers

Email me my report

"*" indicates required fields

Driftrunner Utility Mining Vehicle

Driftrunner Utility Mining Vehicle